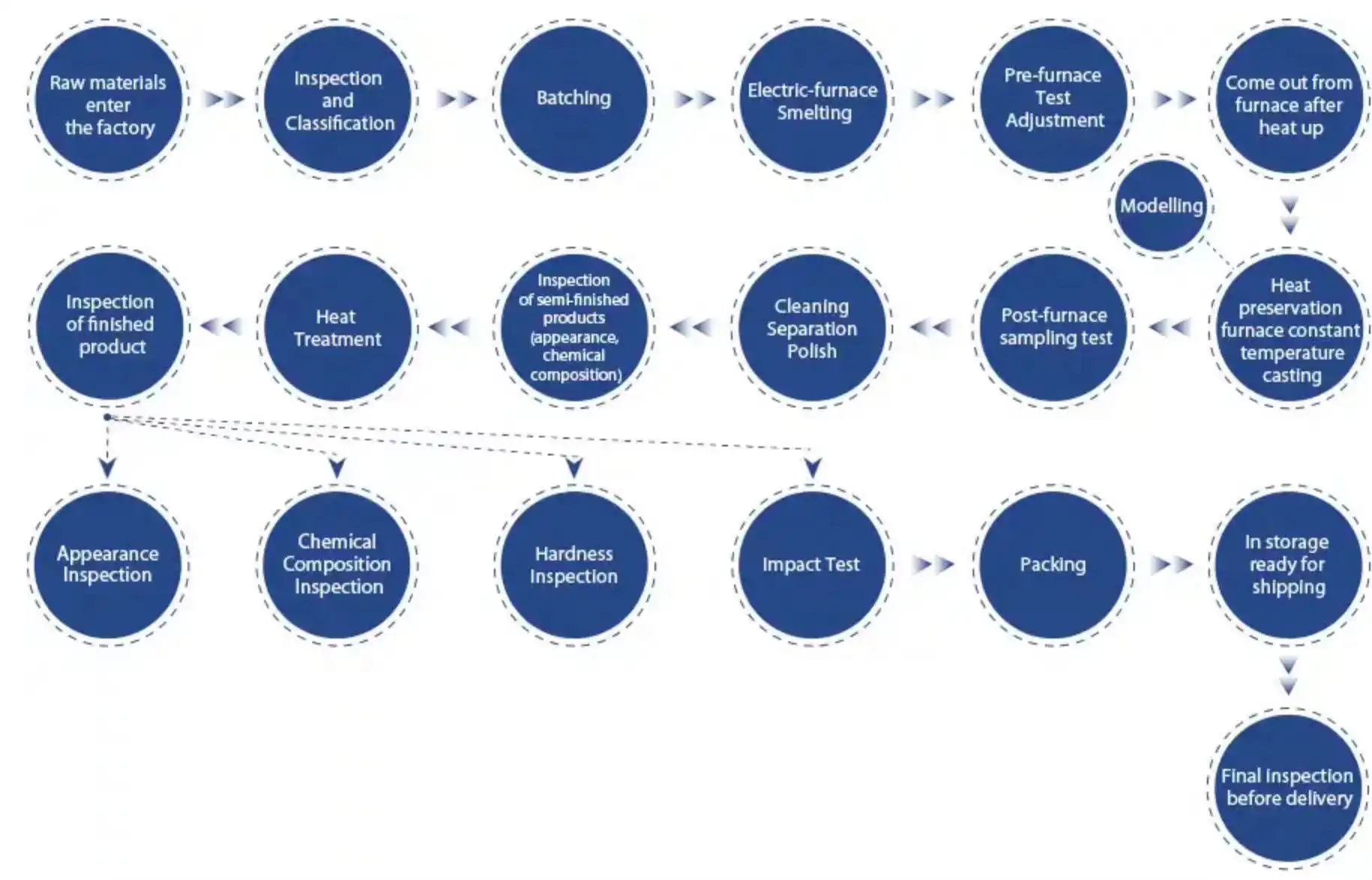

Quality Control Measures: Discussing quality control standards and procedures implemented during the manufacturing process to ensure the consistency and reliability of low chrome grinding cylpebs.

Quality control measures play a pivotal role in ensuring the consistency and reliability of manufactured products. In the realm of manufacturing, particularly in industries dealing with products like low chrome grinding cylpebs, adhering to stringent quality control standards is imperative to maintain customer satisfaction, enhance competitiveness, and uphold brand reputation. This article delves into the various quality control measures employed in the manufacturing process, focusing on the standards, procedures, and technologies utilized to ensure product quality and consistency.

Are Cylpebs Grinding Media Cost-Effective?

Grinding Cylpebs play a critical role in the grinding and comminution processes within industries like mining, cement, and power generation. Cylpebs, a type of grinding media, have been increasingly favored due to their distinct shape and composition. However, assessing the cost-effectiveness of cylpebs as grinding media requires thorough exploration.

How Can Grinding Balls Minimize Contamination in Grinding Processes?

Tainting control is a basic worry in grinding processes across ventures, for example, drugs, food handling, and high level materials fabricating. Fired grinding balls assume a significant part in limiting defilement because of their novel properties and configuration highlights custom-made for spotless and exact grinding tasks.

How Are Grinding Balls Made?

The mining, concrete, and development enterprises, specifically, depend vigorously on Grinding Ball as fundamental parts. These balls are fundamental for delivering the unrefined substances utilized in assembling processes since they are utilized in crushing plants to smash and crush materials into better particles. Several intricate steps are involved in the production of grinding balls to ensure that they meet the stringent requirements for hardness and durability, from selecting the raw materials to the final heat treatment. This article digs into the entrancing assembling interaction of crushing balls and resolves a few habitually posed inquiries about their creation and application.

What is the cost comparison between different types of grinding balls?

What industries typically use casting grinding balls?

Casting grinding balls play a crucial role in various industrial processes, serving as indispensable tools for material reduction and refinement. These robust spheres, typically crafted from high-chrome or low-chrome alloys, have become staples in numerous sectors due to their durability and efficiency. In this comprehensive exploration, we'll delve into the diverse industries that rely on the product, examining their applications and benefits across different fields.

The Impact of Chromium Casting Grinding Balls on Product Quality and Cost Efficiency

.webp)

In the realm of industrial grinding processes, the choice of grinding media plays a pivotal role in determining both product quality and operational efficiency. Among the various options available, chromium casting grinding balls have emerged as a game-changer, offering a unique blend of durability, performance, and cost-effectiveness. This article delves into the multifaceted impact of these specialized grinding balls on product quality and cost efficiency across diverse industries.

What are Ceramic Grinding Balls?

Earthenware Grinding Ball are fundamental parts in the fine crushing or processing cycle of different materials. They are mostly used in mining, ceramics, and coatings, where purity and long-term use are important. These balls are intended to be exceptionally productive in crushing materials to the ideal fineness and are a basic piece of crushing tasks around the world.

What industries commonly use grinding balls?

What are the benefits of using casting grinding balls over other types?

.webp)

In the world of industrial grinding, the choice of grinding media can significantly impact the efficiency and effectiveness of your operations. Among the various options available, casting grinding balls have emerged as a popular choice for many industries. This article explores the unique advantages of using it compared to other types of grinding media.

Innovations in Chromium Casting Grinding Balls: Trends and Future Directions

How does high chrome grinding media contribute to cost savings?

In the world of industrial grinding, high chrome grinding media has emerged as a game-changer, offering substantial cost savings for businesses across various sectors. These specialized grinding balls and cylpebs, crafted with high chromium content, have revolutionized the grinding process, delivering exceptional performance and longevity. Let's delve into the ways high chrome grinding media contributes to cost savings and why it's becoming the preferred choice for industries worldwide.