What are the typical manufacturing processes involved in producing high chrome steel grinding media cylpebs?

How Do Grinding Cylpebs Perform in Different Environments?

_1728977649906.webp)

Grinding cylpebs, widely employed across industries for reducing materials to fine powders, encounter a range of environmental conditions that can influence their performance. Understanding how grinding cylpebs behave in different environments is crucial for optimizing their efficiency and durability.

What Role Do Grinding Balls Play in Cement Production?

What Are Grinding Balls?

Grinding Ball play a crucial role in a variety of industries, particularly power generation, mining, and the production of cement. In grinding mills, these small, round balls are used to crush and grind materials into fine powder. The basic role of crushing balls is to work with the crushing system, guaranteeing proficient and reliable size decrease of materials. This blog will go into detail about grinding balls and answer three important questions that people who search on Google frequently ask.

Can grinding balls be recycled after use?

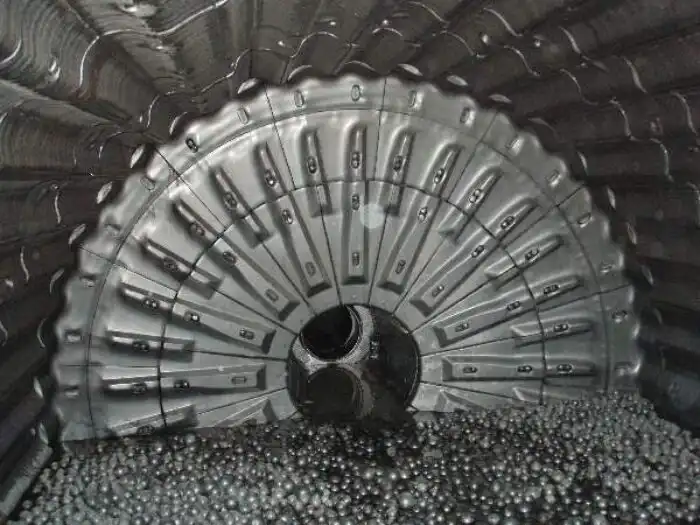

How Chromium Casting Grinding Balls Improve Performance in Ball Mills

In the world of industrial grinding and milling, efficiency and durability are paramount. One of the most significant advancements in this field has been the development and widespread adoption of chromium casting grinding balls. These high-performance grinding media have revolutionized the operation of ball mills across various industries, from cement production to mineral processing. Let's delve into the world of chromium casting grinding balls and explore how they enhance ball mill performance.

Are Ceramic Grinding Balls the Solution for Abrasive Materials?

Ceramic grinding balls are progressively being considered as an answer for grinding grating materials. As businesses look for more productive and savvy grinding arrangements, these balls offer a promising other option. However, would they say they are actually a definitive answer for rough materials? We should investigate this question further.

How to Choose Grinding Balls?

Grinding Ball are fundamental parts in different present day cycles, particularly the mining, cement, and metallurgy regions. Crushing and pounding materials into finer particles is their fundamental capability, enhancing manufacturing processes' efficiency and appropriateness. The effectiveness, strength, and cost-effectiveness of your crushing activities can all be significantly affected by selecting the appropriate crushing balls. You will learn how to select the best grinding balls and the most critical factors in this guide.

How does the hardness of grinding balls impact their performance?

Grinding balls play a critical role in various industries where comminution of raw materials is essential, such as mining, cement production, power plants, and more. Their effectiveness hinges significantly on their hardness, which affects their wear resistance, longevity, and ultimately, the efficiency of the milling process.

What are casting grinding balls and how are they made?

In the world of industrial manufacturing, precision and durability are paramount. One critical component that often goes unnoticed but plays a crucial role in various industries is the casting grinding ball. These small yet mighty spheres are the unsung heroes in mineral processing, cement production, and various other applications where material reduction is essential. Let's dive into the fascinating world of casting grinding balls, exploring their purpose, manufacturing process, and significance in modern industry.

The Role of Chromium Casting Grinding Balls in Modern Manufacturing

In the realm of modern manufacturing, precision and efficiency are paramount. One often overlooked yet crucial component in various industrial processes is the chromium casting grinding ball. These robust spheres play a vital role in grinding, milling, and refining materials across multiple sectors. Let's delve into the world of chromium casting grinding balls and explore their significance in today's manufacturing landscape.

What are the maintenance requirements for high chrome grinding media?

High chrome grinding media play a crucial role in various industries, including cement production, mining, and power generation. These durable components are designed to withstand the rigors of grinding operations, but proper maintenance is essential to ensure their longevity and optimal performance. In this comprehensive guide, we'll explore the maintenance requirements for high chrome grinding media, helping you maximize their lifespan and efficiency.