What is the use of chrome steel ball?

Chrome Steel Ball Chrome steel balls, also known as bearing steel balls or high carbon chrome steel balls, are widely used in various industries due to their excellent properties. These balls are manufactured using chromium alloy steel, which provides high hardness, wear resistance, and durability. In this article, I will delve into the uses of chrome steel balls across different applications, highlighting their importance and benefits.

Fertilizer Production: Selecting the Right Grinding Balls

In the world of fertilizer production, the efficiency of grinding processes can significantly impact the quality and yield of the final product. One key aspect of optimizing these processes is the selection of the right grinding balls. As an industry professional with years of experience in fertilizer production, I understand the importance of this decision. In this comprehensive guide, I will delve into the various factors to consider when choosing grinding balls, ensuring that your fertilizer production operations run smoothly and efficiently.

How do you troubleshoot common issues with grinding balls?

Grinding balls are essential in various industrial processes, particularly in mining and cement production. However, like any other mechanical components, they can face issues that affect their performance and longevity. Understanding these problems and how to troubleshoot them is crucial for maintaining efficiency and preventing costly downtimes.

Grinding Balls in the Steel Industry: Key Considerations

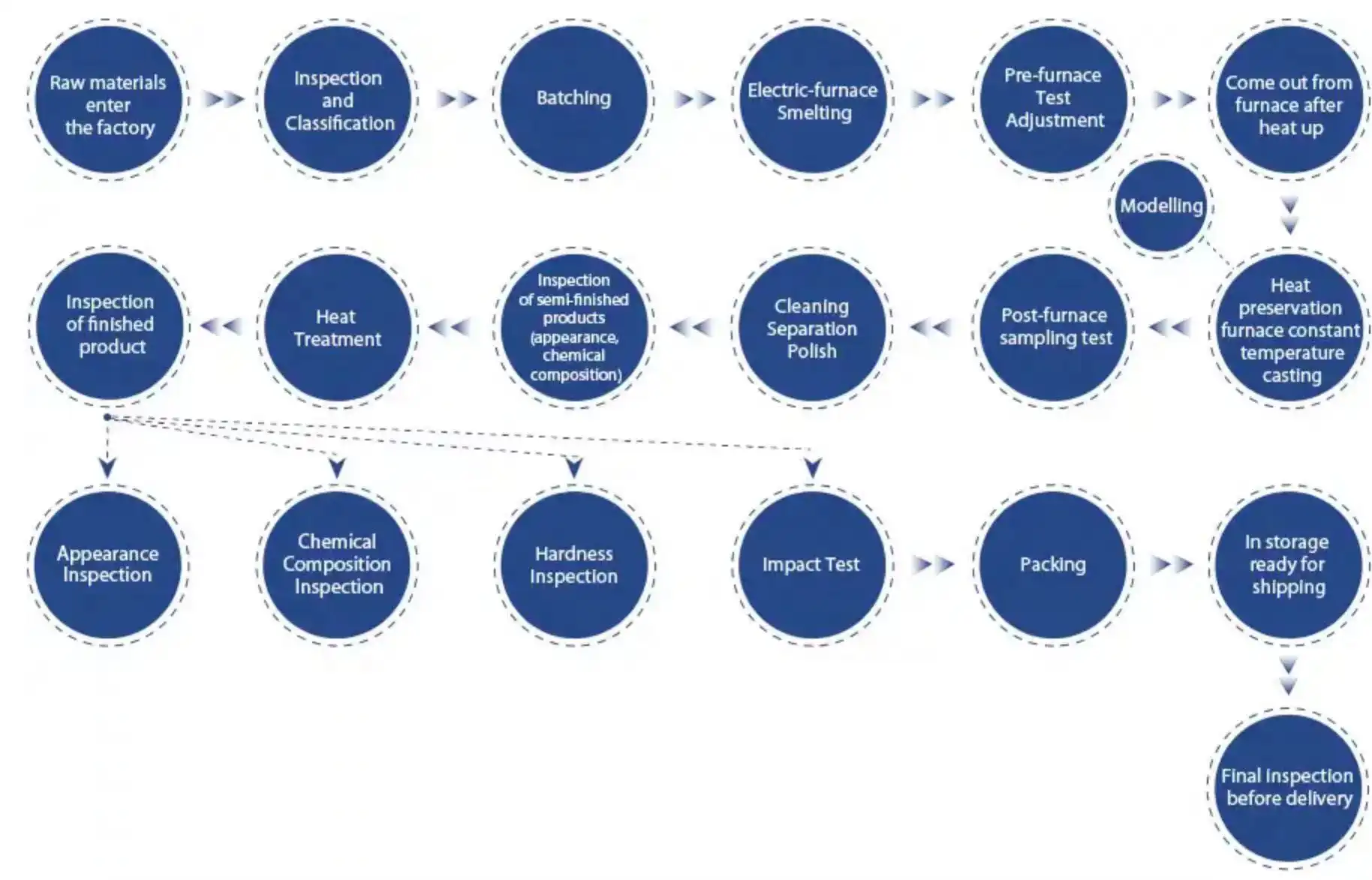

Grinding balls play a pivotal role in the steel industry, where they are used extensively in the process of reducing the size of raw materials such as ore and scrap metal. As a critical component in the production of steel, the quality and efficiency of grinding balls directly impact the overall performance and cost-effectiveness of steel manufacturing processes. In this article, I will delve into the key considerations surrounding the use of grinding balls in the steel industry, covering aspects such as material selection, manufacturing processes, quality control, and sustainability initiatives.

What is the environmental impact of producing grinding balls?

Ensuring Uniformity in Grinding Ball Production

Grinding balls are essential components in industries like mining, cement production, and power generation. The uniformity of these balls directly impacts the efficiency and effectiveness of the grinding process. In this section, I will delve into why ensuring uniformity in grinding ball production is crucial for various industrial applications.

Standards and Specifications for Grinding Balls

Grinding balls play a crucial role in various industries, including mining, cement, and chemical processing, where they are used to crush and grind materials. As such, understanding the standards and specifications for grinding balls is essential to ensure optimal performance and efficiency in industrial processes. In this article, we will delve into the key standards and specifications governing the manufacturing and use of grinding balls.

Their Role of the Grinding Balls in Comminution Circuits

Introduction In comminution circuits, the efficiency of particle size reduction plays a pivotal role in various industrial processes, ranging from mining and mineral processing to cement production and chemical engineering. Grinding balls, often overlooked, are fundamental components in these circuits, influencing the effectiveness and energy consumption of the comminution process. In this article, I delve into the intricate role of grinding balls, their types, materials, and optimization strategies to enhance comminution efficiency.

Market Trends and Forecasts for Grinding Balls

As a pivotal component in industries such as mining, cement, and power generation, grinding balls play an essential role in the comminution process. Understanding the market trends and forecasts for grinding balls is crucial for stakeholders seeking to navigate this dynamic landscape. In this article, I delve into the current state of the grinding balls market, analyze key trends, and offer insights into future forecasts based on credible sources and industry expertise.

Efficiency in Stirred Mills: Impact of Grinding Balls

As the demand for efficiency in stirred mills continues to escalate, understanding the impact of grinding balls is essential for success. By delving into the intricacies of ball dynamics, considering key factors influencing efficiency, and embracing innovations driving progress, operators can optimize their milling operations for maximum performance and productivity.

Understanding Grinding Ball Wear Mechanisms

Grinding ball wear is a critical factor affecting the efficiency and cost-effectiveness of grinding processes in various industries such as mining, cement, and utilities. As a crucial component of ball mills and other grinding equipment, grinding balls undergo wear during operation, leading to reduced efficiency, increased energy consumption, and higher maintenance costs. Understanding the mechanisms behind grinding ball wear is essential for optimizing grinding operations and maximizing productivity.

Load Impact: Effect on Milling Circuits

In the realm of milling circuits, the significance of load impact cannot be overstated. As a pivotal component in various industrial processes, milling circuits play a crucial role in reducing particle size and facilitating material extraction. However, the impact of load fluctuations on milling circuits is a multifaceted phenomenon that demands careful consideration. In this comprehensive analysis, we delve into the intricate dynamics of load impact and its implications for milling circuits, shedding light on key aspects that influence efficiency, performance, and overall productivity.