Grinding Balls: Vital for Cement Industries

Grinding Balls play a pivotal part in the cement industry, where they are utilized to smash and crush crude materials into a fine powder. These balls are regularly made from different materials such as steel, press, ceramic, or indeed elastic, depending on the application and necessities of the cement fabricating handle. In this article, we will dig into the significance of pounding balls in cement generation and investigate their different employments and functionalities inside the industry.

Mining Applications of Grinding Balls

As a pivotal component within the realm of mining operations, grinding balls play a crucial role in the extraction and refinement of minerals. In this article, I delve into the multifaceted applications of grinding balls within the mining industry, exploring their significance, composition, efficiency factors, technological advancements, and broader implications on the environment and economy.

How to Recycle Grinding Balls?

Grinding Ball are fundamental apparatuses in different modern cycles, especially in mining and metal handling. However, their use causes wear and tear, making them eventually unusable in their original form. The economic benefits of recycling grinding balls outweigh the environmental benefits. The efficacy, benefits, and feasibility of recycling grinding balls are examined in this article.

What is the impact of grinding ball composition on milling results?

Top Trends in Casting Grinding Balls: Innovations Shaping the Future of Grinding Media

The world of industrial grinding is experiencing a renaissance, with casting grinding balls at the forefront of this evolution. As industries strive for greater efficiency and sustainability, the demand for innovative grinding media solutions continues to grow. This article explores the cutting-edge trends that are revolutionizing the casting grinding balls sector, offering insights into the future of grinding technology.

What maintenance practices can extend the life of high chrome grinding balls?

High chrome grinding balls are indispensable components in various industries, including cement production, mining, and power generation. These robust spheres play a crucial role in grinding and pulverizing materials, contributing significantly to the efficiency of industrial processes. To ensure optimal performance and longevity of it, proper cleaning and maintenance are paramount. This comprehensive guide will delve into the intricacies of caring for these essential industrial tools, providing valuable insights for professionals and enthusiasts alike.

Sustainable Materials for Grinding Ball Production

Grinding balls are essential components in various industries, particularly in the mining and cement sectors, where they are used to pulverize ores and materials. However, the traditional production methods for grinding balls often involve the use of non-renewable resources and generate significant environmental impacts. In response to growing concerns about sustainability, manufacturers are increasingly exploring alternative materials and production processes. In this article, we delve into the concept of sustainable grinding ball production, examining the materials, methods, and implications for the industry.

How Do Grinding Balls Work?

In a variety of mills, Grinding Ball are an essential component for pulverizing and reducing solid materials into fine powder. These balls are essential to the mining, cement, and other industries that require materials to be reduced in size for further processing or production. They can be used in ball mills, sag mills, or autogenous grinding (AG) mills.

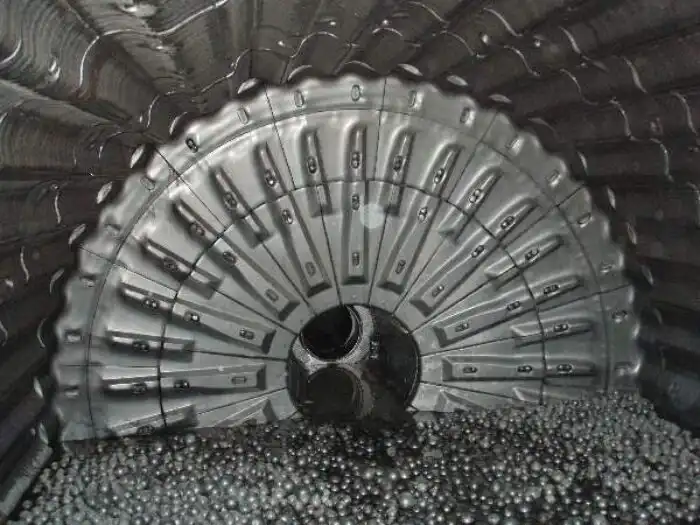

Can you use grinding balls in a SAG mill?

Grinding balls are essential components in the operation of SAG (Semi-Autogenous Grinding) mills, serving to crush ore and reduce it from large chunks into smaller pieces for further processing. SAG mills are primarily used at gold, copper, and platinum mines where they play a crucial role in the comminution of ores. Central to their operation are grinding balls, which are typically made of steel or other alloys and come in various sizes and compositions. These balls are loaded into the mill alongside the mined material to facilitate the grinding process. But can any grinding balls be used in a SAG mill? Let's delve into this question and explore the nuances of their application.

How to Clean and Maintain High Chrome Grinding Balls

.webp)

High chrome grinding balls are indispensable components in various industries, including cement production, mining, and power generation. These robust spheres play a crucial role in grinding and pulverizing materials, contributing significantly to the efficiency of industrial processes. To ensure optimal performance and longevity of it, proper cleaning and maintenance are paramount. This comprehensive guide will delve into the intricacies of caring for these essential industrial tools, providing valuable insights for professionals and enthusiasts alike.

Exploring the Environmental Impact of Casting Grinding Balls in Industrial Processes

In the realm of industrial manufacturing, casting grinding balls play a pivotal role in various processes, particularly in the mining, cement, and power generation sectors. These spherical components, crafted from high-chrome or low-chrome materials, are essential for grinding and pulverizing raw materials. However, as industries worldwide shift towards more sustainable practices, it's crucial to examine the environmental implications of producing and utilizing casting grinding balls. This article delves into the ecological footprint of these industrial tools and explores potential avenues for minimizing their environmental impact.

How is the hardness of high chrome steel grinding media balls measured?

In the world of industrial grinding, the hardness of grinding media plays a crucial role in determining the efficiency and effectiveness of the grinding process. High chrome steel grinding media balls, known for their exceptional durability and wear resistance, are widely used across various industries. But have you ever wondered how the hardness of these robust spheres is measured? Let's delve into the intricacies of hardness measurement for high chrome steel grinding media balls and uncover the significance of this essential characteristic.