What is wear-resistant casting and how does it work?

Do Cylpebs Grinding Media Increase Throughput?

Grinding Cylpebs media are essential components in the efficiency and cost-effectiveness of grinding processes across various industries. These media, which come in different shapes and compositions, play a pivotal role in breaking down materials into finer particles. Among the numerous options available, cylpebs grinding media stand out due to their unique cylindrical shape and specific composition. This distinct form can significantly influence the throughput and overall performance of the grinding process.

How Can Grinding Balls Contribute to Sustainable Mining Practices?

Determining the ideal grinding ball size is pivotal in augmenting the productivity and viability of grinding processes across different enterprises. The decision of ball size straightforwardly influences the grinding proficiency, molecule size appropriation, and generally performance of the processing activity.

How to Test Grinding Balls?

Grinding Ball are fundamental parts utilized in different businesses, including mining, concrete plants, power stations, from there, the sky is the limit. Guaranteeing their quality and execution is significant to upgrading tasks and accomplishing wanted results. This article provides insights into the durability, effectiveness, and overall quality of grinding balls by examining efficient testing techniques.

What factors influence the wear rate of grinding balls?

Grinding balls play a critical role in industries where comminution (the process of reducing particle size) is essential, such as in mining, cement production, and power plants. Understanding the factors that affect the wear rate of grinding balls is crucial for optimizing mill performance and extending their lifespan.

What are high chrome grinding balls made from?

High chrome grinding balls are essential components in various industrial processes, particularly in mineral processing and cement production. These robust spheres play a crucial role in grinding and crushing materials, contributing to the efficiency and effectiveness of milling operations. Understanding the composition and manufacturing process of high chrome grinding balls can provide valuable insights into their performance and applications.

What is the typical lifespan of casting grinding balls?

Casting grinding balls are essential components in various industrial processes, particularly in mining, cement production, and material processing. These robust spheres play a crucial role in grinding and pulverizing materials, but their effectiveness is closely tied to their lifespan. Understanding the typical lifespan of casting grinding balls is vital for optimizing operations, managing costs, and maintaining efficiency in industrial settings.

How Can Grinding Balls Reduce Grinding Media Consumption?

In industries like cement production, mining, and power generation, grinding media is an essential component of the milling process. However, the cost of grinding media can be substantial, especially when considering the large volumes required. Reducing grinding media consumption is not just about cutting costs; it's also about improving efficiency, prolonging equipment life, and minimizing environmental impact. But how can grinding balls contribute to this goal? In this article, we'll explore how the right choice of grinding balls can help reduce grinding media consumption while maintaining or even enhancing operational efficiency.

What is the Hardness of Grinding Balls?

Grinding Ball are a necessary part of a lot of industrial processes, especially mining and ore processing, where they are used to extract valuable minerals from ore. The effectiveness and longevity of grinding balls are directly impacted by their hardness, so knowing their hardness is essential. Hardness impacts how well the balls wear out materials and oppose misshapening under pressure, eventually influencing the effectiveness of the whole processing process.

Can grinding balls be used for both wet and dry milling?

Grinding balls are essential components in ball milling operations, crucial for pulverizing materials into fine particles in both wet and dry conditions. Understanding their versatility is key to optimizing milling processes for various applications. Grinding balls play a vital role in the process of ball milling, which is widely used in various industries for the production of powders and materials. Whether in wet or dry milling applications, these spheres are capable of effectively reducing the size of particles, enhancing mixing processes, and facilitating chemical reactions.

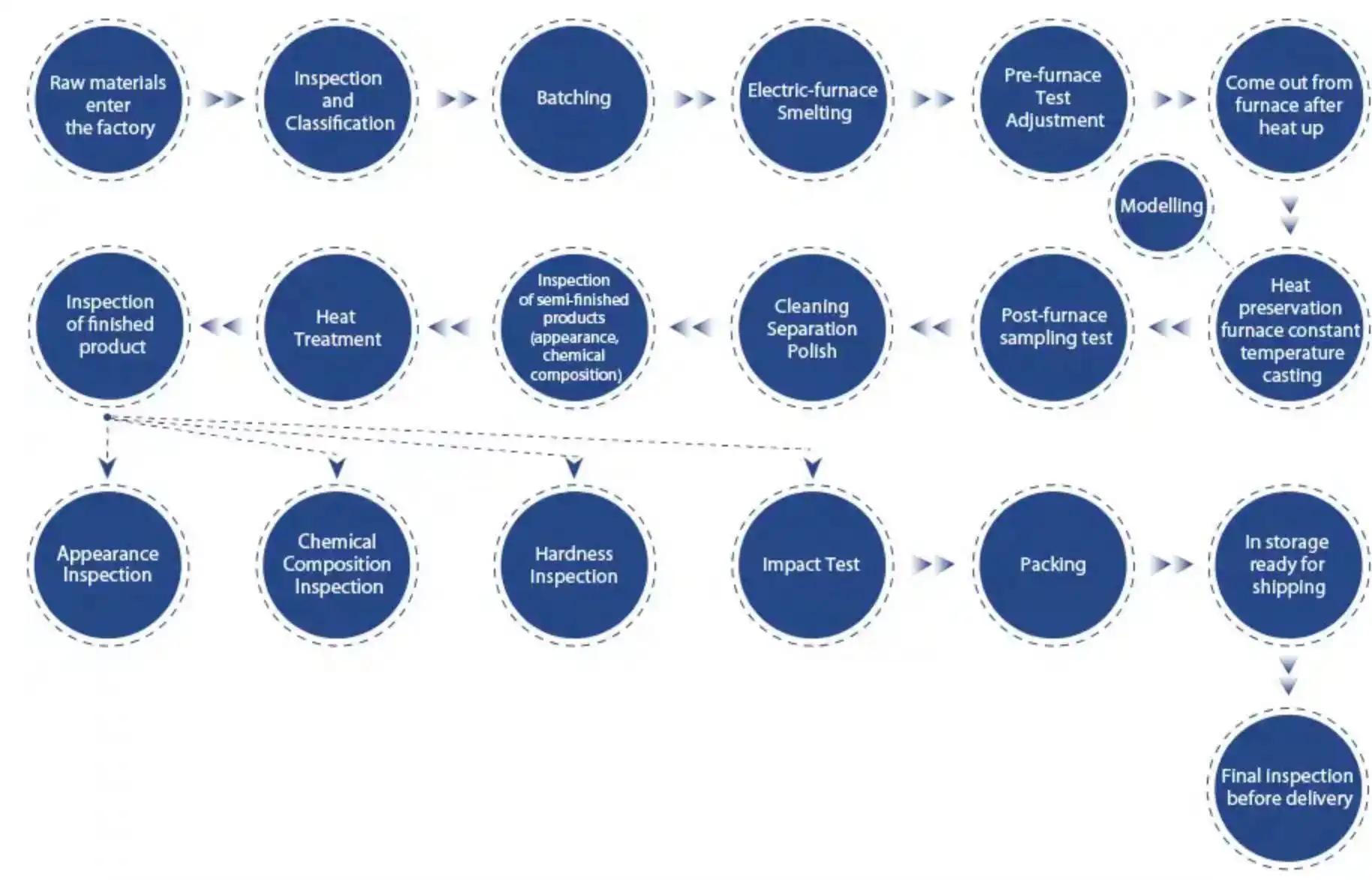

How are high chrome grinding balls produced?

In the world of industrial grinding, high chrome grinding balls play a crucial role in enhancing efficiency and durability. These robust spheres are essential components in various industries, including cement production, mining, and power generation. But have you ever wondered about the intricate process behind their creation? Let's delve into the fascinating world of high chrome grinding ball production and uncover the secrets behind their exceptional performance.

What factors influence the quality of casting grinding balls?

In the world of industrial grinding, casting grinding balls play a crucial role in various sectors, including cement production, mining, and power generation. These spherical metallic tools are essential for breaking down materials into fine particles, and their quality can significantly impact the efficiency and effectiveness of grinding operations. Understanding the factors that influence the quality of casting grinding balls is vital for manufacturers and end-users alike. Let's delve into the key elements that determine the performance and durability of these indispensable grinding media.