Preparing for High Chrome Grinding Ball Installation

Before diving into the installation process, it's imperative to make adequate preparations. This preliminary stage sets the foundation for a successful installation and optimal performance of your high chrome grinding balls.

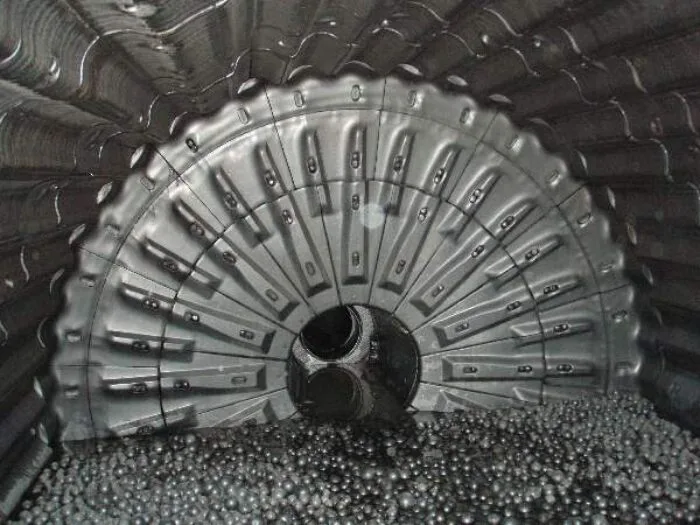

Begin by thoroughly cleaning the mill or grinding chamber. Remove any residual material, debris, or worn-out grinding media. This step is crucial as it prevents contamination and ensures the new high chrome grinding balls can function effectively from the outset.

Next, inspect the mill for any signs of wear or damage. Pay close attention to the mill liners, as they play a significant role in the grinding process. If you notice any cracks, excessive wear, or other issues, address these before proceeding with the installation of new grinding balls.

It's also essential to consult the manufacturer's specifications for your particular mill and the high chrome grinding balls you're using. These specifications will provide valuable information on the optimal ball charge, size distribution, and other parameters that will influence the installation process.

Prior to introducing High Chrome Crushing Balls, it's urgent to direct intensive readiness to guarantee ideal execution. Assess the grinding mill's condition first, then clean the inside to get rid of any debris or old media. Additionally, as wear on mill components like liners and bearings can have an impact on the grinding process's effectiveness, it's critical to check for it. Furthermore, accumulate every single fundamental instrument and wellbeing hardware to work with a smooth establishment. Legitimate arranging guarantees that all means are required to limit personal time and expand the adequacy of the new crushing balls in the processing activity.

The Installation Process of High Chrome Grinding Balls

With preparations complete, you can proceed with the actual installation of the high chrome grinding balls. This process requires attention to detail and adherence to best practices to ensure optimal grinding efficiency.

Start by determining the appropriate ball charge for your mill. This is typically expressed as a percentage of the mill's volume and can vary depending on the specific application and material being ground. Overcharging or undercharging the mill can lead to inefficient grinding and increased wear on both the balls and the mill itself.

When loading the high chrome grinding balls, it's crucial to maintain a proper size distribution. A common practice is to use a mixture of different ball sizes, with larger balls at the feed end of the mill and smaller balls towards the discharge end. This arrangement helps optimize the grinding process by providing efficient breakage of larger particles at the start and fine grinding towards the end.

As you load the balls, do so gradually and evenly. Avoid dumping large quantities of balls at once, as this can lead to uneven distribution and potential damage to the mill liners. Instead, add the balls in smaller batches, allowing them to settle naturally within the mill.

During the installation, pay attention to the ball-to-powder ratio. This ratio affects the grinding efficiency and can be adjusted based on the specific requirements of your grinding operation. A higher ball-to-powder ratio generally results in finer grinding but may also increase energy consumption.

The installation of High Chrome Grinding Balls requires careful attention to detail to ensure effective operation. Start by following the manufacturer’s guidelines for the specific type of mill being used. Carefully load the grinding balls into the mill, ensuring an even distribution to promote uniform grinding. It may be necessary to fill the mill to a certain percentage of its total capacity for optimal performance. During the installation, monitor the alignment and positioning of the balls to avoid any imbalances. Once all balls are in place, conduct a test run to confirm that everything operates smoothly before returning to full production.

Post-Installation Considerations for High Chrome Grinding Balls

Once you've completed the installation of your high chrome grinding balls, there are several important considerations to ensure optimal performance and longevity.

Initial operation should be conducted at a reduced speed to allow the new balls to settle and establish a stable grinding pattern. Gradually increase the speed to the normal operating level over a period of time, monitoring for any unusual vibrations or sounds.

Regular monitoring of the grinding process is crucial. Pay attention to factors such as power draw, product fineness, and throughput. These indicators can help you assess the effectiveness of your high chrome grinding ball installation and make any necessary adjustments.

Implement a routine maintenance schedule for your grinding system. This should include regular inspections of the mill liners, monitoring of ball wear rates, and timely top-ups of grinding media. Proactive maintenance can significantly extend the life of your high chrome grinding balls and maintain grinding efficiency.

It's also important to keep detailed records of your grinding operations. Track parameters such as ball consumption rates, grinding efficiency, and energy usage. This data can be invaluable for optimizing your process over time and making informed decisions about future media selections.

Remember that the performance of high chrome grinding balls can be influenced by various factors, including the characteristics of the material being ground, mill operating conditions, and the overall grinding circuit configuration. Be prepared to make adjustments as needed to optimize your grinding process.

Subsequent to introducing High Chrome Crushing Balls, there are a few key post-establishment contemplations to remember. To begin with, screen the crushing system intently during the underlying activity to distinguish any anomalies or likely issues. Customary support checks are fundamental to evaluate wear rates and guarantee that the balls are proceeding true to form. It's likewise valuable to keep definite records of functional boundaries, which can give bits of knowledge to future upgrades. Also, you might want to think about making a schedule for routine inspections and parts replacements. This will help keep the grinding balls and milling equipment working well and last longer.

Conclusion

Proper installation of high chrome grinding balls is a critical step in ensuring efficient and effective grinding operations. By following these steps and considerations, you can maximize the performance and lifespan of your grinding media, leading to improved productivity and cost-effectiveness in your industrial processes.

For more information about our high-quality high chrome grinding balls and expert advice on their installation and use, please don't hesitate to contact us at sunnyqin@nhgrindingmedia.com. Our team of specialists is ready to assist you in optimizing your grinding operations.