Introduction:

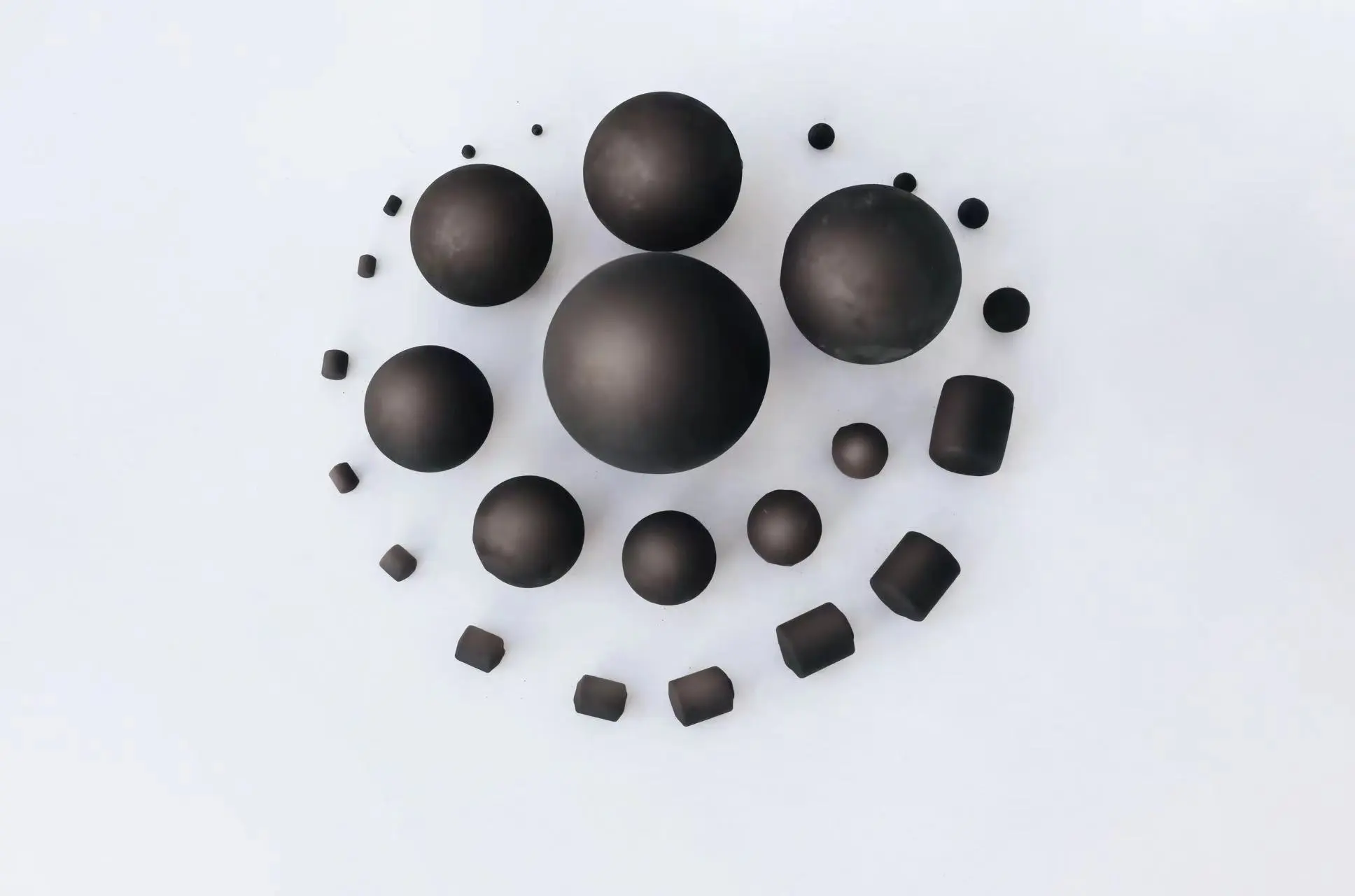

As someone deeply involved in the field of materials processing, I have always been intrigued by the various methods and tools used to achieve efficient grinding. Among these tools, grinding media play a crucial role in ensuring the desired particle size reduction and product quality. In this article, I will delve into the advantages of using cylpebs as grinding media, exploring their applications, benefits, and the factors influencing their efficiency.

What are grinding media balls used for? Grinding media balls, commonly made of steel, are essential components in the process of comminution, where particles are reduced in size by mechanical forces. These balls are utilized in various industries, including mining, cement, and chemical processing, to facilitate the grinding of raw materials or final products.

In mining operations, pounding media balls are utilized in ball plants to smash and pound metal particles, empowering the extraction of profitable minerals. Essentially, in the cement industry, these balls help in pulverizing clinker and other crude materials to create cement of craved fineness. In addition, in chemical preparing plants, pounding media balls are utilized in crushing applications for materials such as colors, colors, and ceramics.

What businesses or applications commonly utilize cylpebs crushing media?

Cylpebs, round and hollow pounding media with a somewhat decreased shape, offer particular points of interest over conventional circular pounding balls in certain applications. Businesses such as cement fabricating, mineral handling, and control era commonly utilize cylpebs due to their particular characteristics and benefits.

In the cement industry, grinding media are favored for pounding clinker and gypsum due to their higher surface zone and contact focuses with the fabric. This expanded surface interaction improves the crushing productivity and advances better molecule measure dissemination, driving to made strides cement quality and strength.

In mineral preparing plants, cylpebs are utilized in auxiliary and tertiary pounding stages, especially for milder metals. Their prolonged shape and decreased contact surface region compared to balls result in lower wear rates and vitality utilization, making them cost-effective crushing media for better molecule liberation.

Additionally, in control era plants, cylpebs discover application in coal pounding plants. Their round and hollow shape encourages the crushing of coal to better sizes, upgrading combustion effectiveness and diminishing emanations. Additionally, the decreased wear and upkeep necessities of cylpebs contribute to lower working costs and made strides plant unwavering quality.

What factors affect the grinding efficiency and particle size distribution when using cylpebs?

A few variables impact the crushing productivity and molecule measure dissemination when utilizing cylpebs as grinding media. Understanding and optimizing these variables are significant for accomplishing wanted handle results and item quality.

Material Composition: The composition of cylpebs, counting the sort and rate of alloying components, essentially impacts their execution. High-quality cylpebs made from amalgam steel with fitting hardness and durability show prevalent wear resistance and crushing efficiency.

Ball Charge Administration: The dispersion and estimate of cylpebs inside the process, known as the ball charge administration, influence crushing energy and vitality utilization. Ideal ball charge administrations guarantee productive molecule breakage and minimize overgrinding, driving to a smaller molecule measure distribution.

Mill Working Parameters: Working parameters such as rotational speed, process filling level, and slurry thickness impact the pounding prepare and item quality when utilizing cylpebs. Controlling these parameters inside ideal ranges is basic for maximizing pounding proficiency and minimizing vitality consumption.

Feed Characteristics: The measure dissemination, hardness, and dampness substance of the bolster fabric altogether affect pounding execution when utilizing cylpebs. Appropriate characterization and alteration of bolster properties empower the choice of fitting pounding conditions for accomplishing the wanted molecule measure conveyance.

Conclusion:

In conclusion, cylpebs offer distinct advantages over traditional grinding media balls in various industrial applications. Their unique shape, increased surface area, and tailored properties contribute to higher grinding efficiency, finer particle size distribution, and reduced wear rates. By understanding the factors influencing cylpebs' performance and optimizing grinding parameters, industries can enhance their process efficiency, product quality, and economic viability.

References:

[1] H. Benzer, "Modeling and simulation of a fully air swept ball mill in a raw material grinding circuit," Powder Technology, vol. 150, no. 3, pp. 145-154, 2005.

[2] G. P. Soares, L. G. Austin, A. L. Trass, "Population balance model approach to ball mill optimization in iron ore grinding," Proceedings of XXII International Mineral Processing Congress, vol. 1, pp. 1-6, 2003.

[3] M. J. Daniel, A. S. Kurlov, "Cement grinding optimisation," Minerals Engineering, vol. 14, no. 11, pp. 1249-1259, 2001.

[4] N. Arbiter, H. Harris, "Selection and sizing of primary autogenous and semi-autogenous mills," Minerals and Metallurgical Processing, vol. 1, no. 3, pp. 121-124, 1984.

.webp)

.webp)

.webp)

.webp)

.webp)

- 副本.webp)