What factors affect the lifespan and performance of cast iron ball mill liners?

As a seasoned engineer with years of experience in the field of materials science and industrial equipment, I have often pondered over the intricate factors that influence the efficiency and durability of ball mill liners, particularly those made of cast iron. In this comprehensive article, I will delve into the various elements that impact the lifespan and performance of cast iron ball mill liners. By exploring the factors affecting the efficiency of ball mill grinding, understanding the function of liners in a ball mill, and examining the influences on mill wear, we can gain valuable insights into optimizing the operation of ball mills in various industrial settings.

Heat Treatment Techniques for Grinding Balls

How Can Grinding Cylpebs Enhance Your Grinding Efficiency?

Are Grinding Balls Subject to Wear and Tear During Transportation?

What factors affect the performance and durability of casting alloy steel hammers?

As a metallurgist deeply engaged in understanding the nuances of steel alloys, I've delved into the factors influencing the performance and durability of casting alloy steel hammers. In this comprehensive article, I'll dissect the key elements that impact the longevity and effectiveness of these essential tools.

The Significance of Grinding Ball Hardness

What Sets Grinding Cylpebs Apart from Other Grinding Media?

What Factors Influence the Pricing of Grinding Balls?

What is a Ball Mill?

A Ball Mill Balls is a kind of crushing gadget used to crush materials finely. It comprises of a pivoting barrel shaped shell that is to some extent loaded up with balls, regularly made of steel, ceramic, or elastic. These balls grind the material by tumbling inside the mill, making a blend of effect and steady loss powers. Ball mills are utilized in different enterprises, including mining, concrete, drugs, and synthetic compounds, because of their capacity to create fine and uniform molecule sizes.

What is the difference between forged and cast grinding balls?

What industries commonly use grinding media?

Grinding media plays a crucial role in various industrial processes, significantly impacting efficiency and product quality. These robust materials, typically in the form of balls or cylpebs, are essential components in grinding mills used across multiple sectors. Let's delve into the diverse industries that rely on the product and explore how these unassuming yet indispensable tools contribute to their operations.

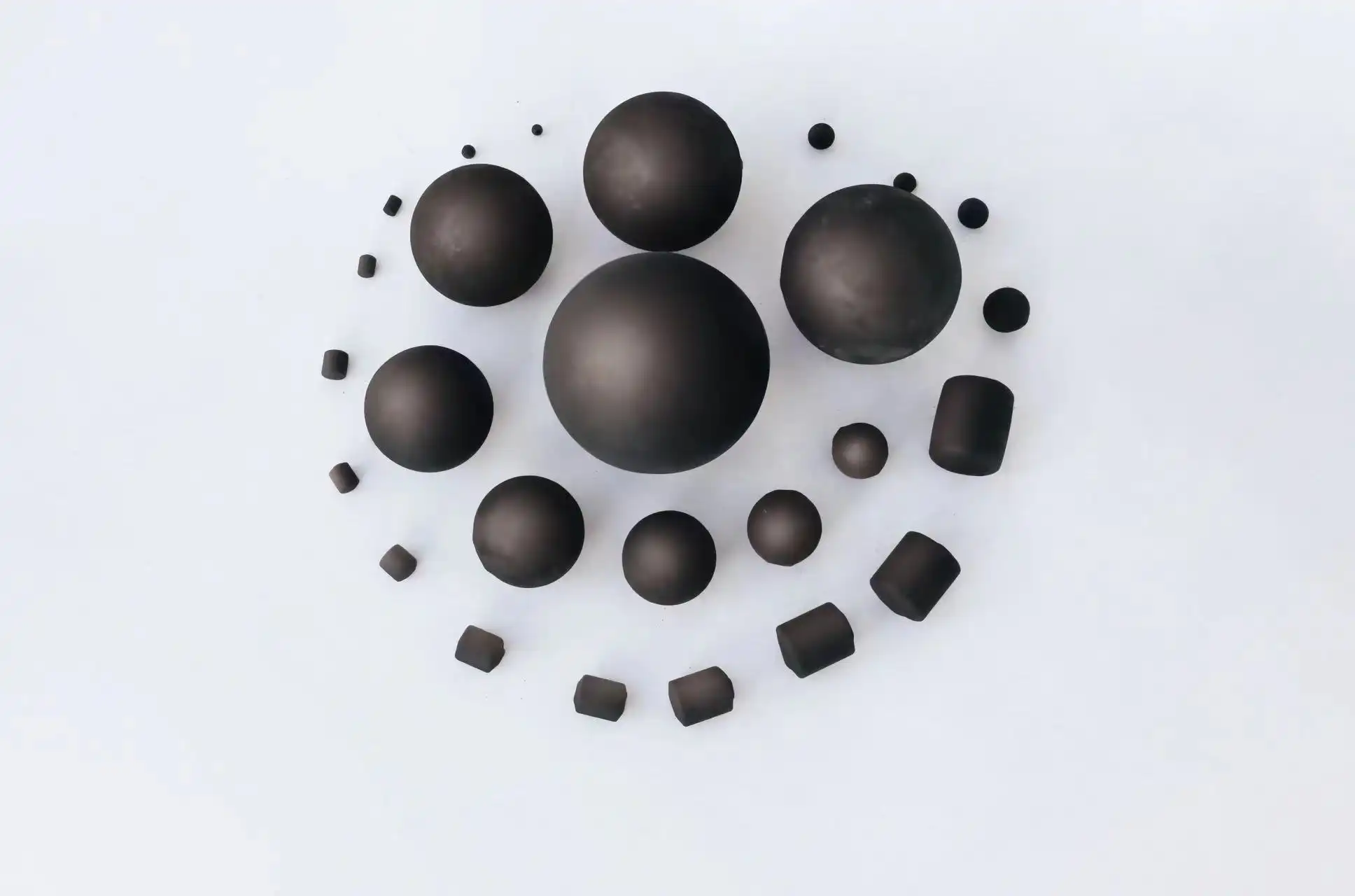

What materials are used to make high chrome grinding media?

High chrome grinding media are essential components in various industrial processes, particularly in mining, cement production, and mineral processing. These specialized grinding balls and cylpebs play a crucial role in reducing the size of materials through impact and abrasion. The effectiveness of these grinding media largely depends on their composition and manufacturing process. Let's delve into the materials used to create high chrome grinding media and explore their unique properties.

_1728977924822.webp)