Are Grinding Balls Eco-friendly?

Grinding balls, while serving as a cornerstone in various industrial applications, are especially pivotal in the mining and mineral processing sectors. Their key role is to facilitate the size reduction of raw materials into finer particles, which is an indispensable step in the effective extraction of valuable minerals and metals. However, the use of grinding balls has sparked growing concern and discourse regarding their environmental implications.

What are the benefits of high-chrome grinding balls?

In the realm of industrial materials used for grinding purposes, high-chrome grinding balls have garnered significant attention for their superior performance characteristics. These balls are widely employed in industries such as mining, cement production, and power generation, where efficient grinding of ores, cement clinker, coal, and other materials is crucial for operational success.

Top 7 Uses for High Chrome Grinding Balls

High chrome grinding balls have become an indispensable tool in various industries, offering unparalleled durability and efficiency in grinding processes. These robust spheres, typically composed of high chromium steel alloys, have revolutionized material processing across multiple sectors. In this comprehensive guide, we'll explore the top seven applications of the product, shedding light on their versatility and importance in modern industrial processes.

What Industries Use Grinding Balls?

Grinding balls, also known as grinding media, are spherical objects used in ball mills for various industries to grind and blend materials for use in mineral processing, paints, pyrotechnics, ceramics, among others. Understanding the diverse applications of grinding balls across different industries sheds light on their critical role in manufacturing processes and material refinement.

How do you dispose of used grinding balls?

Grinding balls are vital components used in the mining and mineral processing industries to pulverize ore and extract metals such as gold, copper, and iron. These balls endure rigorous conditions, undergoing substantial wear and tear during the grinding process. As they reach the end of their operational life, proper disposal becomes crucial to mitigate environmental impact and adhere to regulatory guidelines.

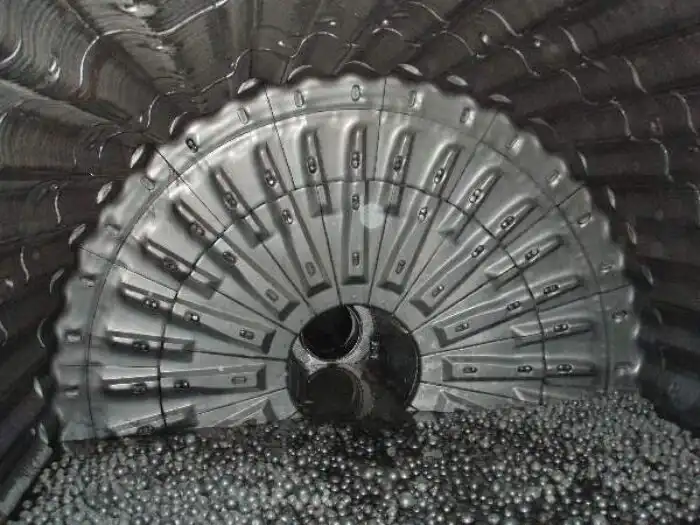

Steps to Installing High Chrome Grinding Balls

High chrome grinding balls are essential components in various industrial processes, particularly in mineral processing and cement production. These durable, wear-resistant balls play a crucial role in grinding and reducing the size of materials. In this comprehensive guide, we'll explore the steps to properly install high chrome grinding balls, ensuring optimal performance and longevity in your grinding operations.

How do high chrome steel grinding media balls influence product quality?

In the world of industrial grinding processes, the choice of grinding media can significantly impact the final product quality. High chrome steel grinding media balls have emerged as a superior option for many applications, offering a unique combination of durability, efficiency, and product enhancement. This article delves into the intricate relationship between high chrome steel grinding media balls and product quality, exploring how these specialized components contribute to superior outcomes in various industries.

How to Prevent Grinding Ball Breakage?

Grinding balls, integral to a range of industrial applications, are especially vital within the mining and cement sectors. Their primary function is to reduce ores and various materials to a finer consistency, which is essential for streamlined extraction or processing. Despite their importance, the issue of grinding balls breaking frequently poses a significant challenge to these industries. Such breakage can disrupt operations, resulting in extended periods of inactivity and escalating costs.

What certifications should grinding ball suppliers have?

Exploring the Benefits of High Chrome Grinding Balls

In the world of industrial grinding and milling, high chrome grinding balls have emerged as a game-changer. These robust, wear-resistant media are revolutionizing various industries, from cement production to mineral processing. Let's delve into the remarkable advantages of the product and discover why they're becoming the preferred choice for many manufacturers.

How do high chrome steel grinding media balls compare to ceramic media?

When it comes to industrial grinding processes, the choice of grinding media can significantly impact efficiency, cost-effectiveness, and overall performance. Two popular options in the market are high chrome steel grinding media balls and ceramic media. Both have their unique characteristics and applications, but how do they stack up against each other? Let's dive into a comprehensive comparison to help you make an informed decision for your grinding needs.

What are the maintenance requirements for using high chrome steel grinding media balls?

.webp)

High chrome steel grinding media balls are essential components in various industrial grinding processes. These durable and efficient grinding tools require proper maintenance to ensure optimal performance and longevity. In this comprehensive guide, we'll explore the crucial maintenance requirements for high chrome steel grinding media balls, helping you maximize their effectiveness and extend their lifespan.